Ambitious targets force you to think differently. When DFDS committed to a 75% intensity reduction in well-to-wheel CO₂e emissions by 2030 for our road transport and land activities, we knew efficiency improvements alone wouldn't cut it. We needed something more radical, something that would fundamentally shift how we power our operations. Electrification was the obvious answer, but usually it comes with a high price tag.

Introducing the terminal tractor

Walk through any RORO terminal and you'll notice the constant hum of activity. Terminal tractors – those workhorses that shuttle trailers between vessels and yards – are the unsung heroes of port logistics. These tug masters represent a significant chunk of our terminals' emissions, making them the perfect way to continue our electrification journey.

Terminal tractors are practically designed for electrification. Short routes within defined terminal boundaries, constant stop-start cycles, predictable charging windows during operational breaks. Unlike long-haul trucks that need extensive range, these machines work in a controlled environment with known energy demands. The question wasn't whether we should electrify. That part had already been established. The real challenge was working out how.

The fork in the road

In Pendik, we found ourselves at a crossroads that probably looks familiar to anyone trying to decarbonise their fleet. Option one: buy brand-new electric terminal tractors. Option two: find a way to convert what we already have.

The decision took longer than we'd anticipated. New electric tractors carry a high price tag, and the market-leading manufacturers weren't quite ready to meet demand. This is specialised equipment, and the industry's still catching up. But there was another issue that kept coming up. We had perfectly good diesel tractors – some nearing the end of their operational life, sure, but structurally sound. Scrapping them entirely would be wasteful, considering the embedded emissions in existing equipment. We would prefer to extend the useful life of what we already have, keeping materials in use, and avoiding unnecessary waste. Retrofitting started looking less like a compromise and more like the smarter choice.

Finding the right partners (and universities along the way)

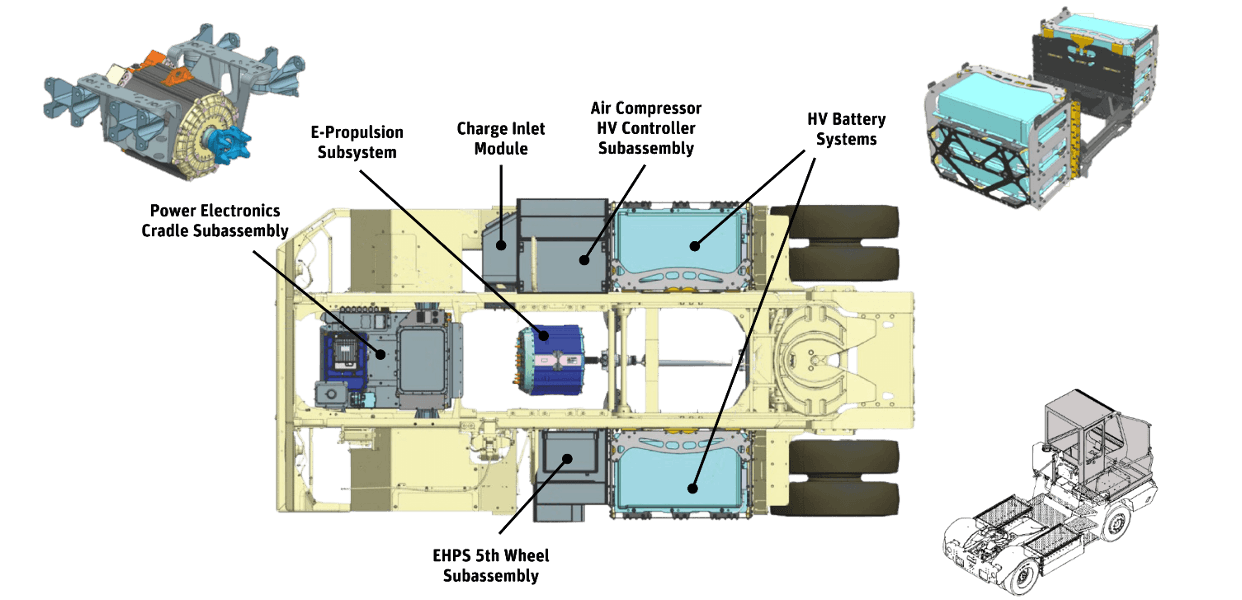

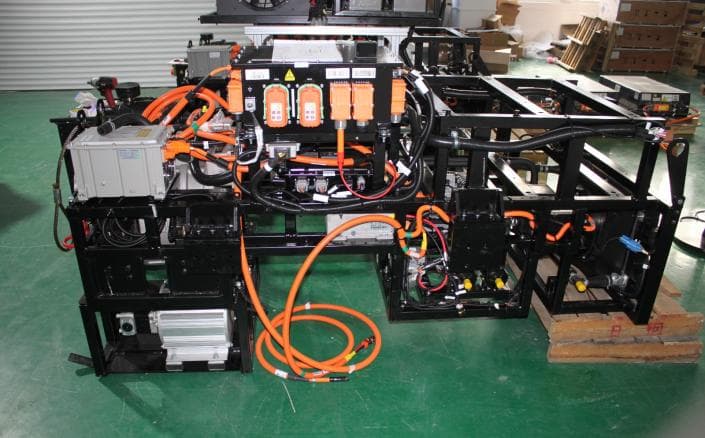

At this point, we brought in Yıldız Technical University in Istanbul – because when you're pioneering something like this, academic rigour doesn't hurt. As Associate Professor Dr. Alp Tekin Ergenç from the university's Faculty of Mechanical Engineering puts it, electrification offers both environmental and economic benefits for the port sector, with electric propulsion systems leading the transformation through zero exhaust emissions, low operating costs, and high energy efficiency. More than that, this kind of conversion enhances resource efficiency by extending the lifecycle of existing diesel vehicles. What emerged was a brilliant three-way collaboration: industry expertise from Portunus, research capability from the university, and operational knowledge from DFDS Pendik terminal personnel. The conversion involved removing the diesel engine and transmission, then installing a 260 kW peak power electric motor, powered by a 198 kWh battery pack. The kit includes sophisticated battery management systems, DC fast charging capability, and cabin air conditioning. Even the vehicle's pneumatic and hydraulic systems are driven by independent electric motor - significantly reducing noise and completely eliminating vibration and exhaust emissions.

We spent months on analysis, including a detailed evaluation of repair & maintenance costs before even touching a spanner.

Four phases, one vision

Phase 1: assessment (or, how we chose our guinea pig)

We chose the oldest machine in our fleet at Pendik, a vehicle practically at the finish line of its operational life. We evaluated financial models, operational requirements, and market alternatives. The numbers kept pointing us back to retrofitting.

Phase 2: the conversion

The actual conversion happened in just four days inside our Pendik workshop. Four days! Our team swapped out the diesel engine for an electric motor and battery system, all designed for optimal energy efficiency, performance, and safety.

Before we started, we'd trained our workshop engineers and technicians on EV maintenance. We even gave the first converted unit a fresh coat of paint - strictly speaking, unnecessary, but we wanted people to notice and ask questions about what we were doing.

Phase 3: the real test

Converting a tractor is one thing. Making sure it actually works in the chaos of real port operations is something else entirely.

We ran a 33-day operational test under realistic conditions. The converted tractor spent 19% of its time removing trailers from vessel decks, 64% on full-load in-and-out vessel operations, and 17% positioning trailers in the yard. Proper work - not some sanitised test scenario. The results were encouraging. On a single full charge, the tractor delivered between 7.5 and 8.5 hours of operational runtime - enough for most single-shift operations. Average operational speed clocked in at 10.2 km/h, with a max of 26.4 km/h, covering 371.4 kilometres during testing.

What really impressed us was the thermal stability. Electric motors run cooler and more predictably than diesel engines, and energy consumption stayed consistent throughout the test period.

Phase 4: getting everyone on board

After delivery, we held training sessions for operators covering everything from basic usage to battery management. We took this further by dedicating two operators specifically to this electric tug master to get detailed feedback from the people actually using it day in, day out. Their insights help us identify and address any weak points for future conversions.

The team that made it happen

This retrofit project stands as a testament to teamwork, innovation, and perseverance. From concept to completion, every member played a vital role, design engineers reimagined systems, the workshop team, especially İsmail Karıncalı and Ufuk Buga, turned plans into reality, and operators Süleyman Göktaş and Uğur Demir proactively embraced the new technology, providing real-world feedback that shaped improvements. Leaders from project partners Portunus (Sami Özdemir) and Yıldız Technical University (Assoc. Prof. Dr. Alp Tekin Ergenç ) worked tirelessly to ensure the momentum stayed strong.

Special congratulations to my team at Pendik terminal — your commitment turned vision into reality and set a benchmark for future conversions.

The numbers that made us smile

Let's talk money, because it’s crucial. Retrofitting an existing tractor costs roughly 55% less than buying a new electric one – a substantial saving that gets the job done just as effectively. Now, you might argue that the old diesel tractor we're converting still has residual value—and you'd be right. But even if we account for what that unconverted diesel unit could fetch on the market, we're still looking at savings between 45% and 48%.

Then there's maintenance. Over an eight-year period, we're looking at maintenance costs that are about 65% lower for the retrofitted electric tractor compared to keeping an equivalent diesel unit running.

But here's what really matters – the emissions savings. We crunched the numbers based on our 2024 data, comparing B7 diesel consumption from our regular tug masters against the retrofitted unit. It turns out that our electric tractor avoids an average of 32 kg CO₂e per hour of service. Every single hour. That's possible because the electricity powering it comes from 100% certified renewable sources. And when you factor in the circular economy benefits, the environmental case becomes even more compelling. The financial logic practically makes the decision for you. The environmental logic seals the deal.

What the operators think (and a word about silence)

Operationally, the unit was almost identical to the diesel machines. No steep learning curve, no performance compromise, just cleaner operation. There are a few differences, though. The electric tractors run much quieter. At first, that sounds like an unqualified win. But in a busy port environment, that silence can actually be dangerous: people rely on hearing equipment approach. So, we fitted light indicators to compensate.

Charging requires a bit more planning than simply refueling with diesel, but a full charge handles most operations comfortably, and operators adapted quickly. Speaking of operators – they love these machines. Zero negative feedback so far, which tells you something important about the technology's maturity.

The learning curve ahead

Nothing's perfect. Right now, these converted tractors are new to our maintenance teams. When something goes wrong – and occasionally, things do – it takes longer to diagnose and fix than with our battle-tested diesel fleet. That's the reality of pioneering new technology. But as we gain experience, those troubleshooting times will drop.

What comes next

This pilot project proved that retrofitting terminal tractors from diesel to electric isn't just feasible – it's financially sensible and operationally sound.

The next step involves a thorough review of the project, bringing in other terminals across our network to evaluate how this solution performs under different geographical and commercial conditions. Each terminal has its own operational patterns, climate considerations, and cargo profiles – factors that could affect performance and economics.

Once we've gathered insights from multiple locations and analysed the test results comprehensively, we'll make informed decisions about how to expand the programme. It's about building on what we've learned from Pendik while ensuring the approach works across our diverse terminal network.